|

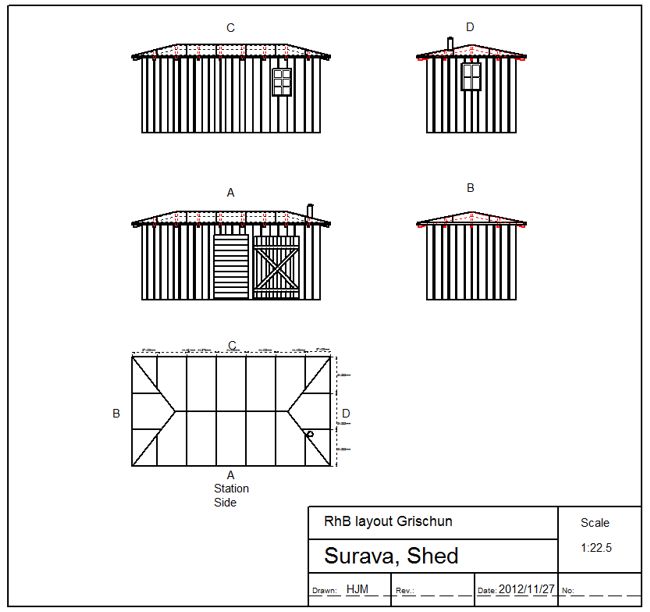

The revised design

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It took a bit of fiddling and adjusting here and there - ít was almost like working in the LGB design office - until it looked right. Three-quarter views are just not as good as the square-on variety, but “in der Not frisst der Teufel Fliegen”.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The roof has been simplified.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

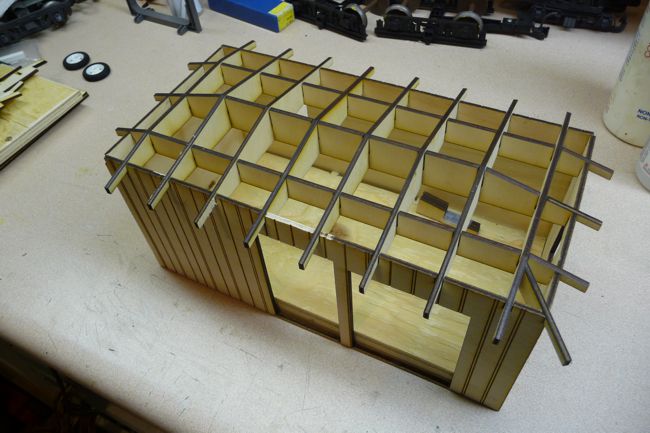

The number of roof joists has been adjusted (reduced), this will require hand-fitting the corner joists.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test sample made from styrene.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

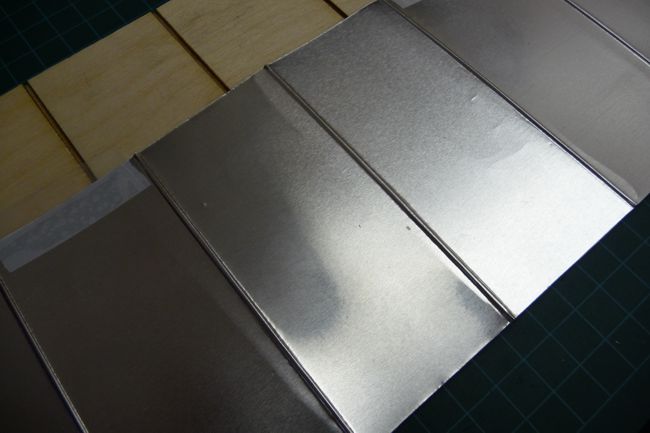

Fixture and tool to produce standing seam roofing using cookie sheet aluminum as raw material.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The original shape of the tool generates a round seam, in order to get a more pointed seam I tried a pizza cutter ... and then decided to modify the original tool. Half the story when scratch building is seeing the possibilities of “stuff” even if it is intended for a completely different application.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Next was the staining test. Using two of the surplus walls I applied the first coat - the Minwax designation is “Driftwood”. The next coat is called “Slate”, this was applied less evenly to leave the “Driftwood” shine through to some extent.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The difference between artificial and natural light is quite evident from the two pictures.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

”First Generation” shed, the roof joists are spray painted with automotive primer.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To be continued

|