|

|

|

|

|

|

Ladder Roadbed Preda - Muot - Seedorf

|

|

|

|

|

|

|

|

|

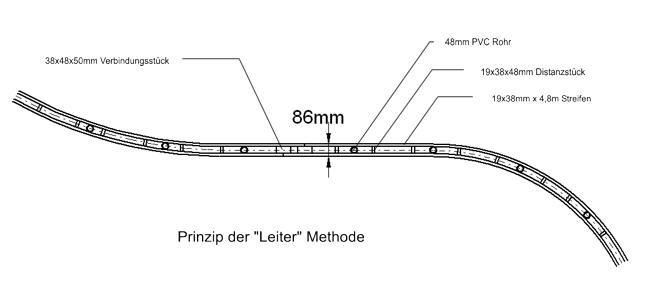

Spring of 2008 was the start of roadbed construction. Using the popular ladder method with PVC tubing for uprights and strips of TREX for the track support. Blocks of TREX are inserted as spacer.

|

|

|

|

|

|

|

Basic principal

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The above picture shows the end of a tube which has been bevelled using a band sander. Beveling allows for more precise positioning and it is easier to drive the tubes into the ground. Using tubing means less ground to be displaced and as a bonus the ground fills the inside of the tube, too. An additional advantage is that the roadbed strips contact only one point on the circumference of the tube and provided one attaches the fasteners at the correct angle it will be almost impossible to end up with kinks or tensions in the roadbed.

|

|

|

|

|

|

|

|

|

First tubes in place at the Muot end of Preda

|

|

|

|

|

|

|

|

Test with the long Kiss coach

|

|

|

|

|

|

|

|

|

The critical section on the Preda side of the tunnel under the stairs required a slight realignment of the plan to get the largest possible radius. And as insurance the corner of that concrete slap will be chopped and rounded.

|

|

|

|

|

|

|

|

|

Strips of TREX

|

|

|

|

|

|

|

The first order of TREX came as 2x6 boards in 16 foot length, talk about heavy! Heavy enough to have them delivered. Ripping the strips took plenty of elbow grease and a a few of the ElCheapo blades for the circular saw. The follow-up order was changed to 1x8 in 12 foot length. Flexible and light enough to fit into the Chevy Venture.

|

|

|

Prior to placing additional uprights there was a bit of clearing on the schedule.

|

|

|

|

|

|

|

|

|

Overgrown right after the tunnel under the stairs

|

|

|

|

|

|

|

|

More excess growth around Muot ...

|

|

|

|

|

|

|

|

... and still more growth

|

|

|

|

|

|

|

Bulbs had to be dug up and at least some of them transplanted.

|

|

|

|

|

|

|

|

Placing the PVC-tubes went quickly, Clamping the first strips of TREX happened on a hot day and two days later I discovered that the strips kept their shape even when the clamps were removed. Bonus! More roadbed, less overgrowth

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The pictures show the large plywood template used to maintain the minimum radius of 1500mm in all those locations were it is impossible to establish a physical centre point for instance in the lake.

|

|

|

|

|

|

|

|

|

|

|

Next page

|

|

|

|

|

|